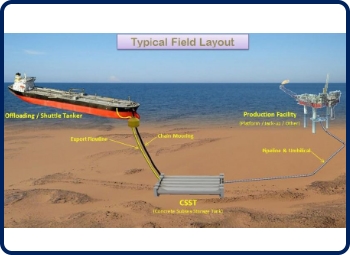

Concrete Subsea Storage Tank (CSST)

Tensa has developed a low cost oil storage system – CSST – that may be ideal for your oil storage needs. Sub-sea concrete oil storage is nothing new – it’s been around for 50 years. What is new is the ability to install and readily relocate your storage unit to alternative field locations at minimal cost, the ability to moor your offtake tanker to the storage tank and the incorporation of a membrane to separate the oil and ballast water. All of the above are achieved by using very simple and easy to build tubular shapes.

The CSST is designed for oil export to Shuttle Tankers. The CSST has a built-in tanker mooring system to accommodate the tanker during its offtake.

KEY FEATURES

- No Cyclone Evacuation – the CSST remains safely on the bottom during cyclones. It can even remain operational during cyclones thereby minimising production downtime. The CSST is designed for the 100 year cyclonic storm, even in water depths as shallow as 20m. Compared to an FSO this can give an increase of up to 10 days of production each year in cyclonic locations.

- Self-Installable – the CSST has been specifically designed for low cost installation. Ths tank will float, has multiple isolated buoyancy chambers and is towable with normal vessels. For shallow water installation CSST only requires the tow tugs needed for getting it to site. For water depths over 50m an extra dumb barge is required. The CSST does not require any expensive pre-laid moorings, nor does it require any seabed preparation – only a relatively level seabed. No rock ballast is required after installation.

- Re-Locatable – the CSST is easily relocatable to an alternate site using tugs. Recovery from the bottom is via a vessel mounted de-ballasting spread that uses air to replace the seawater and refloat the unit. No heavy lift equipment is required.

- Low-CAPEX – the CSST can be offered on lease basis with no upfront CAPEX. In terms of Operations & Maintenance costs, only an annual ROV survey is recommended.

- Membrane Separation – produced crude and seawater are kept separated by an internal synthetic membrane. Seawater ballast is supplied and returned via a separate line from the production facility, ensuring that ballast water is clean before being discharged.

- Designed for easy construction – by using tubular sections, the CSST can be built using conventional precast post-tensioned construction methods used for the construction of bridges and elevated freeways. The unit can be launched from a slipway or quickly assembled in a dock using precast elements.

For more information and exact specifications, download the product sheet here.